Eco-Friendly Research Technology

Hyundai Motor Company has been devoted to developing high-efficiency, zero emission clean technology

Future Vision of Hyundai Commercial Vehicle

Satisfy the practicality, reliability, and originality of commercial vehicles.

EV

Elec City, HMC’s zero emission bus, is the fruition of its designers’ ceaseless effort to satisfy the practicality, reliability, and originality of commercial vehicles. The exquisite combination of the CV engineers’ experience and expertise is embodied in this innovation, which is commensurate with the era of smartization.

The new model, Elec City, has reestablished the nature of modern mass transportation with its modern design, which is comparable to that of advanced countries. It also suggests the prospect and philosophy of Hyundai CVs.

Development History

In 2010, Elec City was successfully test-driven during the 2010 G20 Seoul Summit. This is the fruition of its designers’ ceaseless effort to satisfy the practicality, reliability, and originality of commercial vehicles.

In 2010, the first generation was developed (test-driven during the 2010 G20 Seoul Summit).

In 2013, the second generation was developed.

In 2018, the third generation was entered mass production.

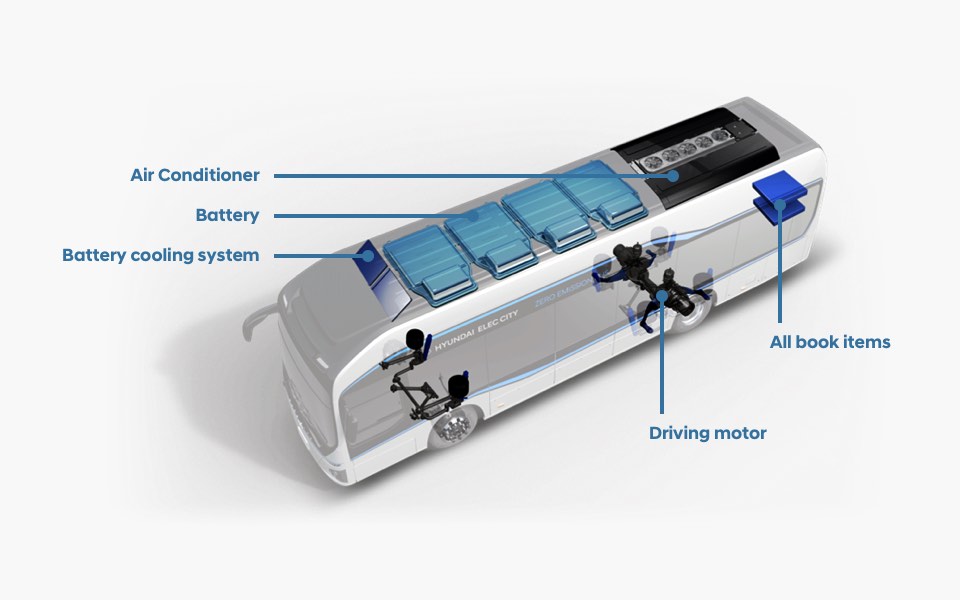

Main System Configuration

A battery is mounted on top of the roof, while different electrical devices are fitted in the engine room on the rear side of the vehicle. Also, the driving motors are directly mounted on both rear wheels.

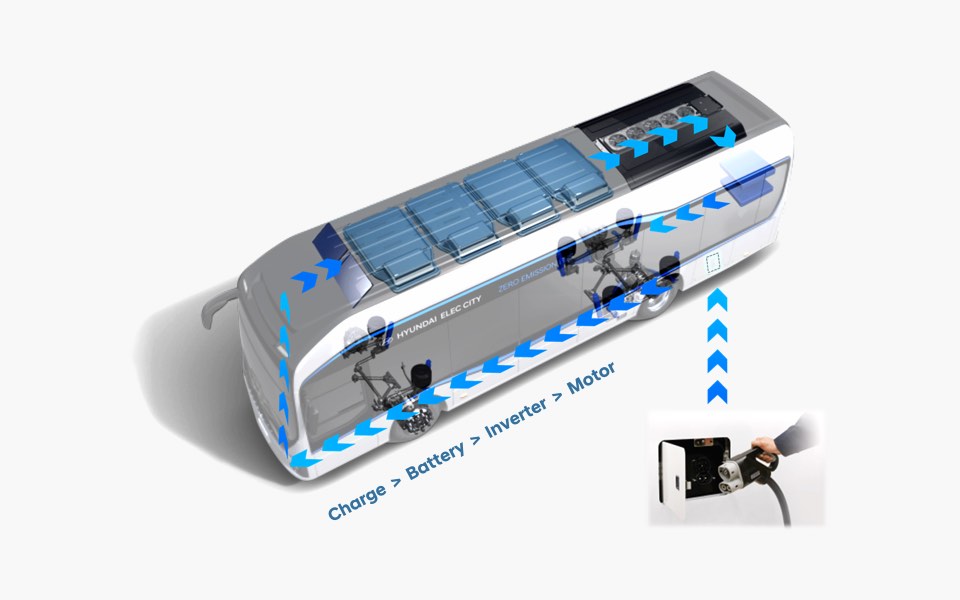

Power System

A fast battery charger is used to charge the high-voltage battery. The charged AC voltage is converted into DC voltage to ultimately drive the motor.

CNG Hybrid

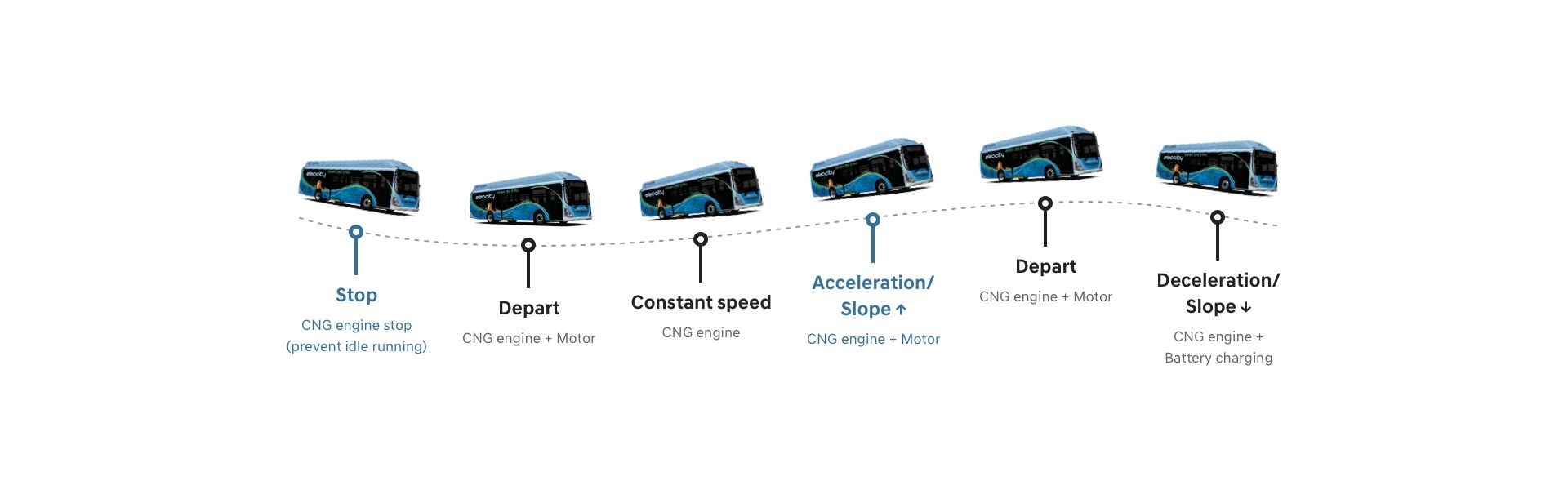

As a hybrid city bus equipped with a CNG engine, Blue City boasts of 30% better fuel efficiency than the existing vehicle (based on km/l). The hybrid city bus shows remarkable advantages in the stop-and-go urban driving pattern. In other words, it shows a much more improved fuel economy.

Specifically, when slowing down, hybrid buses regenerate braking energy into electric power, which is stored in its battery. This stored energy is used to support a driving force through the motor when they begin speeding up after departing.

If the quantifying 30% improved gas mileage is based on one CNG city bus, you can reduce fuel costs worth approximately KRW 7,000,000 every year, or about 22-ton carbon dioxide emission. In short, hybrid city buses have made a significant contribution to air quality improvement and energy saving.

Development History

From early 2000, approximately 17,000 CNG city buses were supplied. In 2013, a CNG hybrid low-floor city bus was released. In 2000, a CNG bus was developed. In 2013, a CNG hybrid low-floor bus was developed. In 2015, a CNG hybrid regular bus was developed.

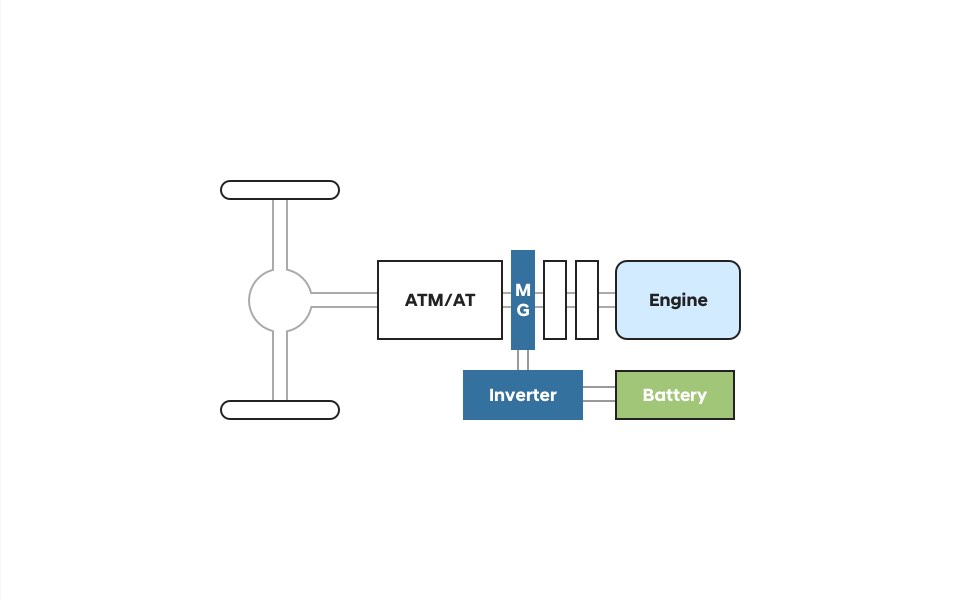

System Configuration

The Blue City CNG hybrid bus has parallel systems, which are advantageous in terms of weight, price, and power performance.

Driving Features

When the hybrid bus departs, only the motor is driven; the engine and the motor are driven together when it accelerates. When decelerating or descending, it recovers energy through the regenerative brake to charge its battery.

FCEV

Just as an electric car does not emit exhaust gas at all, neither does it. Furthermore, it boasts of a more remarkable performance and driving capability than the electric car. Compared with the existing internal combustion engine, its fuel efficiency is more than double. For this reason, it holds the limelight as a car that can use natural energy most efficiently.

Development History

Recognized for its technology, Hyundai Fuel Cell Electric Vehicle (FCEV) was successfully test-driven during the 2006 FIFA World Cup in Germany. Its more commercialized next-generation FCEV is going to be unveiled soon.

In 2006, the first generation was developed (test-driven during the 2006 FIFA World Cup in Germany).

In 2009, the second generation was developed.

In 2018, the third generation was developed.

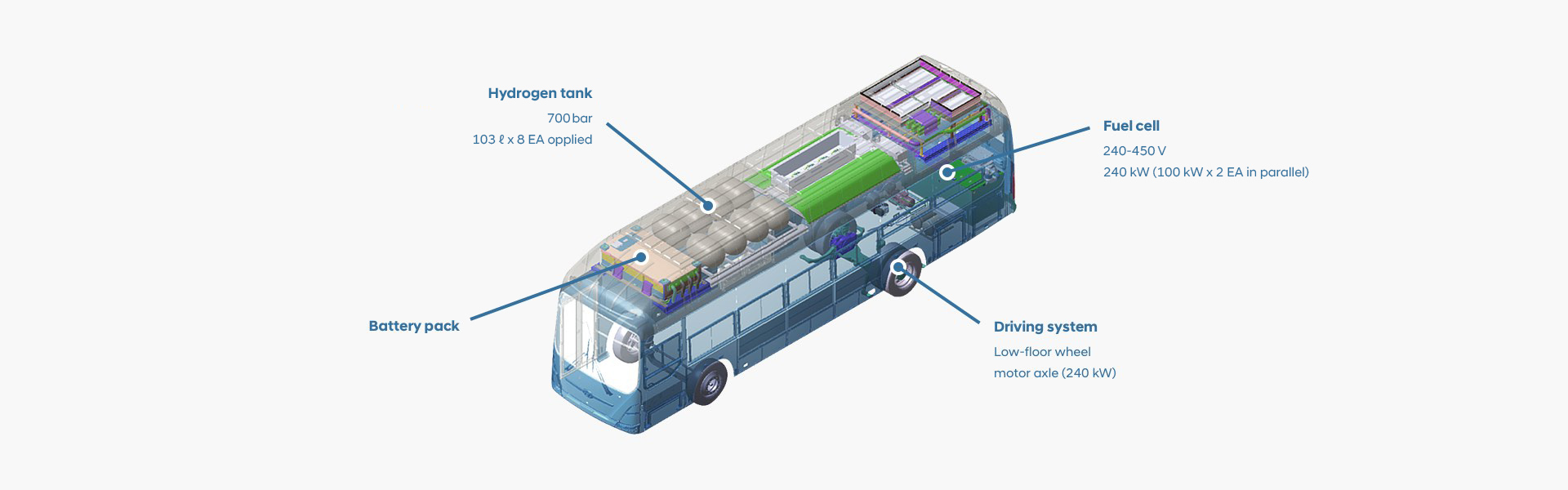

Power System

The electric energy generated from the fuel cell stack is used to drive the motor (Hydrogen tank + Fuel cell + Electric bus driving system). Once hydrogen is input at a hydrogen refueling station, this hydrogen is combined with oxygen in the fuel cells. As a result, water is formed and electricity is generated. The power serves as a power source to drive the wheels.